HIGHSPEED

STAMPING of metal parts

Fast stamping and forming is a modern technology that enables highly efficient and precise production of large series of stamped parts.

Metal pressing is a process in which band materials (steel, stainless steel, copper, and others) are formed using stamping tools at high speeds.

Progresive die stamping is ideal for mass production of high-precision parts. We are supplier of:

- Electronic components

- Automotive parts & sets

- Energy infrastructure & power curcuit parts

- Home appliance mechanisms

- Building elements

- Assembly fittings & units

- Other pressed metal parts

-

Productivity up to 1000 strokes/min

-

Tolerance range: ±0,01 mm

-

Rewindable transport tape option

-

Steel, non-ferrous metals, spring stainless steel

-

Own stamping tool design

-

Serial production > 100,000 pcs / year

- Press schop capacity

-

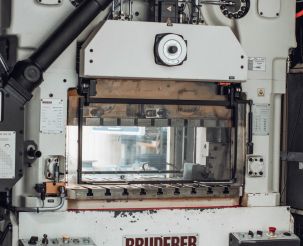

Automatic stamping press BSTA 500-95

-

Powerpress BSTA 25

-

Metal forming press BSTA 41

-

Press machine BSTA 50HL

Applications of Bruderer Presses

Bruderer presses are used in various industries, especially where emphasis is placed on high productivity, precision, and reliability. Typical applications include:

- Production of electronic connectors

- Production of automotive parts

- Production of home appliance parts

- Production of coins and medals

- In central Europe / EU, Czechia / Czech republic

Benefits of fast stamping with Bruderer Presses

- High productivity: Thanks to the high stamping speeds and reliability of Bruderer presses, it is possible to achieve a significant increase in production productivity.

- Cost reduction: Higher productivity and longer tool life lead to lower production costs.

- High quality: Precise stamping and stable construction of Bruderer presses ensure high quality of manufactured parts.

- Flexibility: Bruderer presses are suitable for various types of stamping operations and materials, making them highly versatile in production.

OVERVIEW OF STEEL TYPES USED IN OUR PRODUCTION

- Hot rolled and cold rolled steels

- Microalloyed steels

- Carbon steels

- Deep drawn steels

- Zinc-coated steel

- Stainless steels

- Non-ferrous metals

- Copper, copper alloy

- Aluminium

TYPICAL GRADES

- DD11, DD13, DC01, DC04, S235JR

- 16MnCr5, 25CrMo4, 42CrMo4

- C60S, C67S, C75S, C60S, 51CrV4

- DX51, S250GD, S350GD

- 1.4301, 1.4307, 1,4016, 1.4310

- CuZn37, CuSn6, CuNi18Zn20

- AlMg3, ...